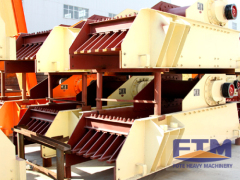

feeding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C |

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Sea |

|---|---|

| Automation: | Automatic |

Product Description

1,production line introduce(feeding machine)

WX-6BF feeding machine

It is a dual track feeding machine which can feed the two different cored wires in the same time.

Feeding machine is equipped with dual sets of roll and an intermediate guide roll, it puts pressure on the cylinder through the upper roll, bottom roll are droved by the motor directly. Upper roll drive an encoder to measure the length of cored wire accurately.

The switch in the console allows the operator to select mode that operate at the same time or continuously.

The feeding speed is determined by the controller and it will appear in the console. The device monitors the length of each stream, it will stop automatically when it gets the length that set before.

In order to install / remove cored wire easily, the wire feeding machine can move.

2,Main technical parameters(feeding machine)

WX-6BF feeding machine

Feeding type: alloy wire, aluminum wire, rectangular wire

Feeding number: 2

Feeding diameter:Ø8-Ø20mm

Feeding speed: 1-7 / s

Host moving speed: 14 / min

Conduit angle: 30 degrees (30 degrees -80 degrees are set by the scene)

Conduit length: 6 meters

Wheelbase: 682mm

Motor Seal: IP55

Control panel seal: IP54

Power: main motor 5.5Kwx2 units (single wire) (7.5KwX2 units single wire)

Use of power: 380V three-phase four-wire system

Host dimensions: 1000X1000X1200mm

Moving rail: 11Kg / m

Operating mode: controlled by PLC, remote control automatically.

We are specialized in the design, manufacture & install offeeding machine. We have a strong technical force, advanced production capacity and high quality after-sale service team. We can provide you feeding machine with comfortable price, great after-sale service.

For more information, please contact us directly. We hope to receive your detailed inquiries soon, and we are looking forward to having the chance of cooperating with you in the near future.