magnetic liner for ball mill

| Payment Terms: | L/C, T/T |

|---|---|

| Place of Origin: | Liaoning |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air |

|---|---|

| Power: | Others |

| Raw Material: | Sheet / Plate Rolling |

| Machine Type: | Roller-Bending Machine |

Product Description

The Magnetic Liner is formed by 3 parts named metal shell\permanent-magnetic body and elastic glue layer.

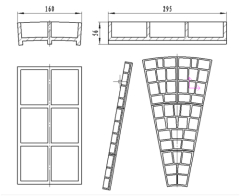

The metal shell is the main part of Magnetic Liner; its function is to protect magnetic blocks from direct impact of external force and it has enough mechanical strength and magnetoconductivity, while the surface of the shell must to have strong magnetic induction intensity. As the protection shell high alloy magnetic steel requires hardness HB=250, tensile strength b=700N/mm2, yielding pointδs=400N/mm2, shrinkage rateΦ=495, impact strength a≥50J/cm2. The tube liners are assembled standard cases with a outer specification L295mm×W160mm×H55mm and cover liners are assembled circular sector cases which determined by mill diameter.

The permanent-magnetic body is the core part of liners; it makes metal shell stick to the ball mill tube and to form a 20-30 mm protection layer which made by broken steel balls and magnetic ore powder.

The glue layer is by using special elastic agglomerant epoxy resin to paste magnetic blocks onto metal shell tightly, due to better flexibility but also plays a buffer of materials & steel ball and magnetic blocks impact.