Stator Winding Pre-forming Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Z1XL1-200/210 |

|---|---|

| Means of Transport: | Ocean |

| Thickness of stator lamination: | 15mm-100mm |

| Stator ID: | 30mm-100mm |

| Max Stator OD: | 160mm |

| Machine productivity: | around 1500pcs/8 hours |

| Displacement of oil pump: | 20F |

| Dirven system: | Hydraulic |

| Power supply: | 380V- 50/60HZ |

| Weight: | 800kg |

| Voltage: | 1500W |

| Dimension: | 1200x700x2200mm |

| Production Capacity: | 30 sets |

| Packing: | Wooden case which is suitable for sea transport |

| Delivery Date: | 35 days |

Product Description

Stator Winding Pre-forming Machine

The Stator Winding Pre-forming Machine is driven by hydraulic system; PLC programming; tooling expansion slice makes the first coil and inter-phase insulation paper in slot adjacent, leaving enough space for second insertion and ensure the quality of successive coil insertion; apply to multi-layer stator winding insertion.

Technical parameter:

Stator I.D | 30~100mm |

Max stator O.D | 160mm |

Thickness of stator lamination | 15~100mm |

Displacement of oil pump | 20F |

Power supply | 380V/50/60Hz |

Machine productivity | around 1500pcs/8 hours |

Weight | 800KG |

Dimension | 1200mm×700mm×2200mm |

Machine main function and characteristic

This machine adopts whole hydraulic system and PCL program.

This machine can adjust the forming stack length by changing washer.

Form the OD, and ID of the stator core coil without forming hang over to facilitate operator to put phase isolator.

After forming, there is no copper wire enamel broken or wire snap.

Changing a new tooling is easy and convenient.

Both slot paper and wedge should not be damaged or turned over. The stator should not be deformation or stator lamination should not be upward. There is no wire enamel broken.

Production capacity ≤15s/set (exclude loading/unloading time)

Primary qualification rate ≥99%, after rework, the rate ≥99.9%

This machine adopts safety grating protection system. Operator need to stand when operating.

Machine adopts two hands simultaneously start button to ensure safety.

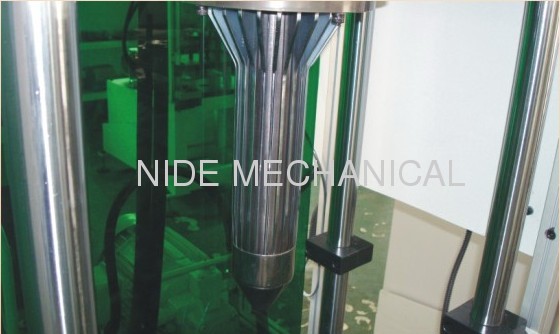

Expansion blade

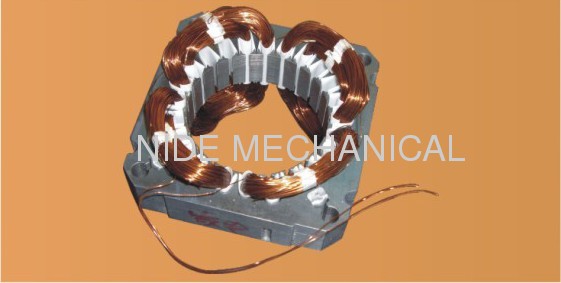

Formed stator