AUTOMATIC COIL WINDING MACHINE MOTOR MANUFACTURING MACHINE FOR SUBMERSIBLE PUMP STATOR BOBBIN TRANSFORMER.

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | RX1-160 |

|---|---|

| Means of Transport: | Ocean, Air |

| Wire Diameter: | 0.2-1.0mm |

| Max Winding Form Diameter: | 250mm |

| Rotation speed: | 3200R.P.M |

| Winding tooling distance: | 210mm-280mm |

| Max Winding Diameter: | 250mm |

| Wire amplitude: | 0-30mm |

| Effective distance between winding shafts: | 550mm-700mm |

| Power supply: | 220V/50Hz |

| Machine productivity: | around 1500 pcs/8 hours |

| Winding ability: | winding 1~8 coils at one time |

| Production Capacity: | 30 sets |

| Packing: | Wooden case which is suitable for sea transport |

| Delivery Date: | 35 days |

Product Description

This kind of Coil winding machine is suitable for multi-connected and multi layer winding;wind 1-8 coils simultaneously at one time; automatic slot change,starting winding position,idling start,idling stop,double-ended stop, automatic reset and automatic start could be set in control system. There are two alternate spindles to facilitate higher output; apply to all kinds of micro motors such as fan motor,pump motor,air conditioner motor,three phase machine,ect. Turns number,wire diameter can be set in the controller.

I. Technical datas:

Diameter of wire | 0.08~1.0mm |

Max stator O.D | 160mm |

Max stack height | 100mm |

Wire amplitude | 0~30mm |

Max winding diameter | 250mm |

Winding tooling distance | 210mm-280mm |

Effective distance between winding shafts | 550mm-700mm |

Rotation speed | 3200R.P.M |

Input | 220V/50Hz |

Air source | 0.5-0.8MPa |

Machine productivity | 1500pcs/ 8 hours |

Dimension | 1550*1250*1300mm |

Weight | ≈ 750kg |

II. Main Components:

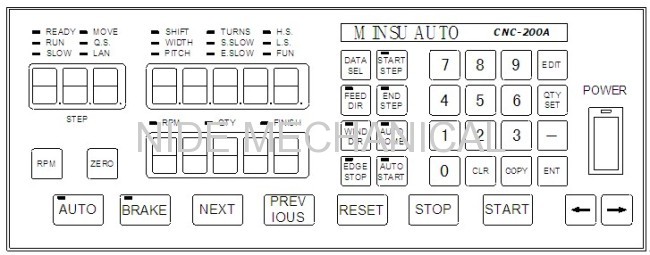

Controller: Mingsu

Inverter: Inovance 1500W

Sensor: Autonics

Bearing: NSK

Button/switch: Schneider

Other electric elements: Delixi/Schneider

III. Machine main function and characteristic:

l. It could be used to do multi-connect and multi-layer winding.

2. This machine has 4 winding heads, In one time, the machine could wind 1-4 groups of coils simultaneously, high output.

3. Tooling change is very fast and convenient.

4. It could save 999 group data, and machine automatic stop once wire run out

5. Free of maintenance.

Winding Controller:

Here you could set the wire diameter,turn number,coil number,and will dispaly the output.And you could pre-set the output,machine will stop automatically once it produces the required quantity

Coils

Coils