Automatic Stator Varnish Dipping Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-ZCJB |

|---|---|

| Means of Transport: | Ocean |

| Working position: | 32 |

| Varnish depth: | 160mm |

| Bracket dimension: | 900mm*300mm |

| Working temperature: | less than 145 C, adjustable |

| Productivity: | 4000-5000pcs/20 hours |

| Power: | 75KW (electricity supply);15KW(diesel supply) |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 30 days |

Product Description

Stator varnish dipping machine is used for stator insulation treatment. The whole process, except for loading and unloading, is completely automatically. Heating time,picth time and temperature could be set. This machine is suitable for induction motor stator. It is mainly applied to stator winding insulation treatment for fractional horsepower motor and industrial Y series motor which is below frame size 132.

Technical Data:

Working position | 32 |

Varnish depth | 160mm |

Bracket dimension | 900mm*300mm |

Productivity | 4000-5000pcs/20 hours |

Working temperature | ≤145 C, adjustable |

Power | 75KW (electricity supply) |

15KW (diesel supply) | |

Dimension | 8000mm*2200mm*2500mm (electricity supply) |

8000mm*4200mm*2800mm (diesel supply) |

Q: What is the production capacity of this machine?

A:It depends on the customer's requirement,we will design the working position number and pitch time accordingly.

Q: What kind of information is required for quotation?

A: We need stator drawing,required production capacity,how many shift per day,and how many hours per shift, then we could provide the proposal accordingly.

Competitive advantages

Variety of application, easy operation.

We directly supply our machines to many countries, like USA, France, Turkey, Iran, India, Brazil, Argentina, Mexico etc.

We could customize machine for our customer as per their stator and requirement.

Information needed for Stator tickling machine inquiry

It will be better if customer could send us detailed drawing including below information.

1. Stator assembly drawing

2. Required productivity

3. Required curing time

4. Other technical requirement

If possible, it will be better if customer can send us samples.

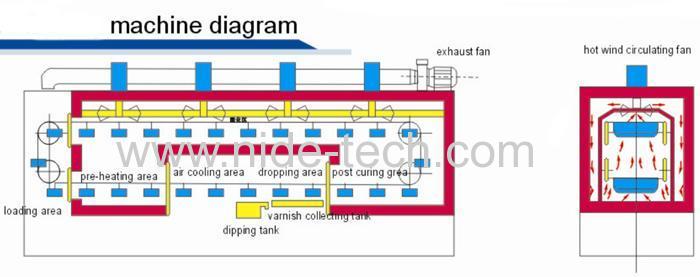

Automatic Stator Varnish Dipping Machine diagram

Stator suitable for this trickling machine