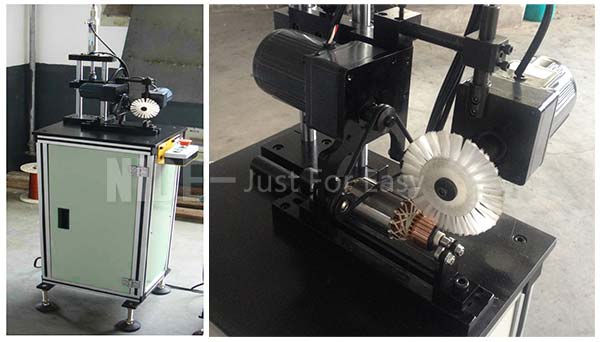

armature commutator automatic rotary brush deburring machine for sale

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-MC-1-A |

|---|---|

| Means of Transport: | Ocean, Air |

| Name: | Automatic brush deburring machine |

| Used for: | Motor armature commutator |

| Color: | Customized |

| Tool: | brush |

| Conditon: | New |

| After-sales Service: | Engineers available to service machinery overseas |

| Brand Name: | NIDE |

| Type: | automatic |

| Size: | small |

| Production Capacity: | 30 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 60 days |

Product Description

Automatic armature commutator metal brush deburring machine

The automatic commutator brush deburring technology machine is precise, easy and time saving to perform.It removes the burrs, cleans the commutator.

The armature commutator brush deburring machine adopts high quality carbide saws and efficient brush deburring system technology . It provides consistent results , eliminates the tedious and imprecise hand chamfering of the copper bars.

The brush deburring machine is supplyed by NIDE mechanical , we provide professional motor manufacturing solutions.

Why choose our brush deburring machine?

Brush Deburring Solution from NIDE

Unlike hand working, The brush deburring produces the same results every time.

Only need manual loading and unloading the armature, and other processes are automatically completed by the brush deburring machine.

All of the burrs are removed and each bar receives the same amount of corner radius.

It avoids create more sharp edges and affect motor brush contact with the commutator,

Ensure the surface area of the copper bars and the commutator's electrical properties

Reduce carbon build-up in the mica slot, avoid electrical shorting between the bars

Non-conductive deburring brushes

The bristles of the deburring brushes are impregnated with Sic(silicon carbide) which is non-conductive ,so that the dust created by deburring process won't cause electrical shorts.

Brush Deburring is Very FAST.

It only takes 10-50 seconds to deburring the armature commutator, greatly improves finishing hours.

In comparison, hand deburring often requires more time and manual labor.

How to Operate

1.Put the rotor on the work slot,

2.Press the start button

3.Automatic deburring

4.Take out the rotor

The armature bursh deburring machine show