Automatic double flyers armature Winding Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-LAW-5B2-F |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Wire diameter range: | 0.25~1 mm |

| Armature diameter: | 20~60 mm |

| Stack length: | 10~60 mm |

| Shaft diameter: | 3~15 mm |

| Commutator diameter: | 18~40 mm |

| Winding speed: | 0~3000 rpm |

| Shaft length: | less than 250mm |

| Armature Slot: | Odd, even slot |

| Production Efficiency: | 22S/PC |

| Power source: | Three phase AC380V 50/60Hz |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 35 days |

Product Description

Automatic double flyers rotor coil winder armature Winding Machine

The armature coil winder Features:

The automatic armature winding machine is suitable for dc motor armature coil winding with three shifts non-stop production

Three type coil winding mode: single slot - single hook, the single slot – double hooks, double layer winding; The armature winder could do twice winding in one slot, four times winding in the two adjacent slots. Total 100 sets parameter can be saved in the HMI as per the armature model No., during winding, the parameter can be dynamic displayed, including shift output, accumulate output, cycle time,etc.

The HMI will automatically alarm if any abnormal happens during production.

Single action, automatic and stepping operation could be switched.

stable swing type fixture, up and down protection mold, protect hooking

automatic wire breaking treatment, can be set to be snap break, there are two sequences: winding firstly then break, break firstly then wind.

Feeding method: cylinder feeding and manual feeding

General technical features :

1.Automatic level:Manually loading/unloading, auto winding.

2.Cycle time:According to the sample

3.Air pressure:0.5-0.7MPa, Voltage:3 phase380V AC±10%,50/60HZ

4.Temperature: -10~40℃,Humidity:40~90%

5.The device is equipped with three color light tower to indicate the machine status.

6.The equipment adopts the quick tooling change-over design, which can realize quick change-over.

7.Different level password protection.

8.The air supply of all equipment must be connected with the air source processing device to ensure the air source quality. It has Low pressure alarm function.

9.Anti-rust treatment on the surface of equipment parts (blackening, electroplating, painting).

10. The main equipment frame adopts welding frame, the upper side adopts aluminum profile and acrylic glass shape, and the host body color is air conditioner grey (RAL7035).

11.Each operation station is equipped with LED lighting.

12.The equipment has safety protection signs, safety parts are yellow, emergency stop button, operation warning signs.

13.The equipment is controlled by PLC and the touch screen is convenient for debugging.

14.Specification:Hook type commutator, double - flyer winding,High speed heavy duty type

Main specification:

Product name | Armature rotor coil winding machine |

Wire diameter: | ¢0.25~¢1mm |

Armature O.D: | ¢20~¢60 mm |

Armature stack length: | 10~60 mm |

Slot type: | straight slot(No more than 36 slots) |

Armature slots number: | Odd, even slot |

Counting Range: | 0~99999 |

Commutator diameter: | ¢18~¢40 mm |

Fly fork speed: | 0~3000 rpm |

Indexing speed: | 0~3000 rpm |

Action process: | Single action, automatic |

Air pressure : | 4~6 Kg/cm2 ,0.5-0.7MPa |

Machine power: | 4KW |

Temperature: | -10~40℃ |

Humidity: | 40~90% |

Power supply: | 3phase 380V±10% 50/60 Hz |

Total weight: | about 1,180 Kg |

Dimension: | 2000(length)×1300(width)×1800(height) mm3 |

Production efficiency: | 800-900set/class(calculated based on 12slots 24hooks, 20turns) |

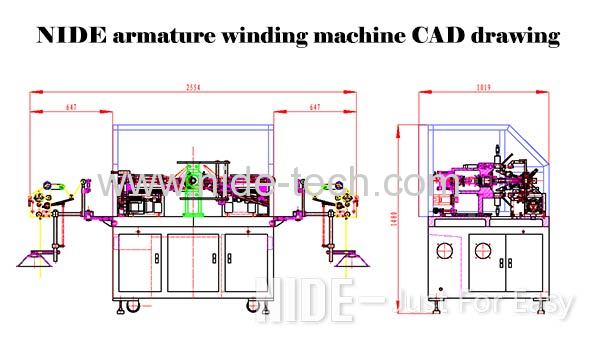

The armature coil winder CAD drawing

The Internal structure of the rotor coil winding machine

The rotor coil winding machine Winding mold