NIDE CE certificated automatic stator coil winding machine for motor winding

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | RXL2-160 |

|---|---|

| Means of Transport: | Ocean |

| Name: | stator coil winding machine |

| Power: | 380V |

| Wire diameter: | 0.2~1.2mm |

| stator OD: | max 160mm |

| stack height: | max 100mm |

| Weight: | about 1000kg |

| Machine certificate: | CCC |

| Condition: | new |

| Dimension: | 2400*1000*2450mm |

| Type: | Middle size |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transport |

| Delivery Date: | 35 days |

Product Description

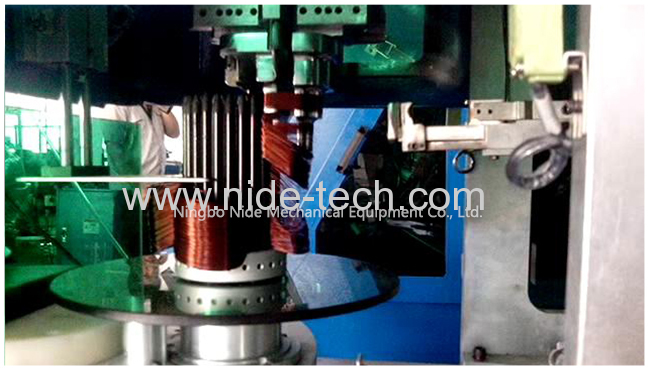

NIDE CE certificated automatic stator coil winding machine for motor winding

(1) Main technical data

Winding head: 1pc

Wire diameter: 0.2~1.2mm

Winding speed: ≤2500RPM

Max stack OD: 160mm

Max stack height: 100mm

Fly fork diameter: 300mm

Transfer number: 1~5 section

Power supply: 380V/50/60HZ 7KW

Weight: about 1000kg

Dimension: L2400*W1000*2450mm

Cerficate: CE

(2) Application:

This coil winding machine is suitable for 2 poles, 4 poles and 6poles coils winding.

(3) Machine main function and characteristic

Winding tooling: each machine has one set winding tooling and three vertical winding forms.

The whole set of tooling can be changed, and it takes about 15min.

The turntable is two stations structure. It adopts servo system to rotate and index transfer form.

Allow three wires winding simultaneously.

Main spindle is controlled by servo motor. The coil turn number accuracy is ±1 turn.

The working rotation speed can be set . Machine has no distinct vibration and noise.

Free of enamel damage and wire snap. Once the copper wire is run out, machine will automatically stop.

PLC can set turn number, winding speed, tooling sunk height, tooling sunk speed and winding direction.

X andY spindle of wire hooker and wire cutter adopts servo system. It can adjust the length of bridge wire and lead wire.

Tooling sunk adopts servo system. The max segment number of tooling sunk is 6.

Coil Winding Machine working process