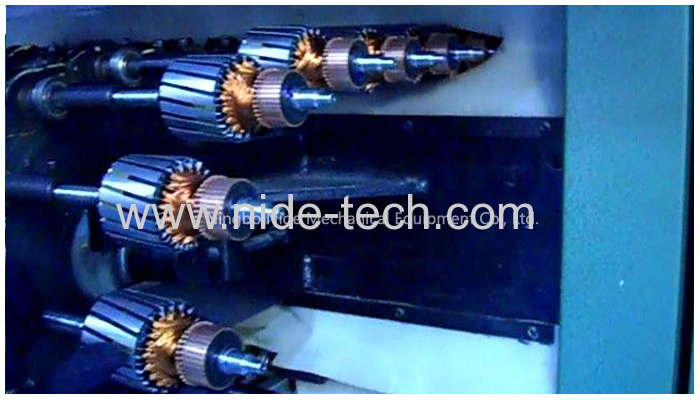

Automatic rotor high temperature varnish trickling machine for electric motor armature

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-ZDG63-260 |

|---|---|

| Means of Transport: | Ocean |

| Heating time: | less than 45 min |

| Tunnel working temperature: | 0~160'C |

| Pitch time: | 0~10 min adjustable |

| Working position: | According to your output requirement |

| Power: | According to your products |

| Machine dimension: | According to your output requirement |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 35 days |

Product Description

Automatic rotor high temperature varnish trickling machine for electric motor armature

(1) Application

This armature/rotor varnish trickling machine is suitable for home appliance, car, and power tooling motor armature rotor.

(2) Machine function and characteristic

The whole process, except for loading and unloading armature, is completely automatically. Armature trickling machine can automatically finish the full procedure of pre-heating, air cooling, trickling (rolling), distribute even and post curing, etc. The automatic production guarantees the good and stable quality standard of the armature.

(3) Main technical data

76 | 76 | 76 | 76 | ZDG50-320 | ||

Working position | 124×2 | 156×2 | 200×2 | 260×2 | 320×2 | |

Position pitch | mm | 76 63 50 | ||||

Heating time | min | ≤45 | ||||

Tunnel working temperature | °C | 0~160°C | ||||

Pitch time | min | 0~10 adjustable | ||||

Power | kw | 28 | 36 | 45 | 54 | 40 |

Machine dimension | m | 4.9×1.6×2.1 | 6×1.6×2.1 | 7.6×1.6×2.1 | 9.8×1.6×2.1 | 3.3×1.6×2.5 |

Weight | t | 3.5 | 4.2 | 4.8 | 5.8 | 3.5 |