Fully auto BLDC Brushless motor stator production manufacturing assembly line

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CIF |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-BDZX |

|---|---|

| Name: | BLDC stator production line |

| Automation type: | fully automatic |

| Certification: | Main electric components are CE certificated. |

| Machine color: | Ral9010 or as Per Customer Requirement |

| Certificate: | CE |

| Size: | large size |

| Condition: | New |

| Transmission method: | Conveyor |

| Customized service: | Available |

| Pachage: | Wooden cage |

| Production Capacity: | 10 sets |

| Packing: | Wooden case which is suitable for sea transport |

| Delivery Date: | 100 days |

Product Description

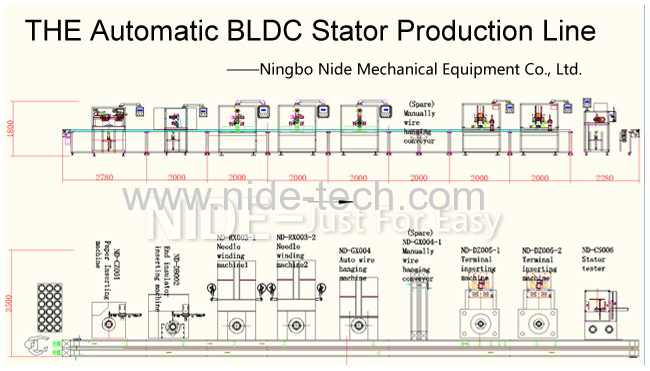

Fully auto BLDC Brushless motor stator production manufacturing assembly line

I.Function and features:

This stator production line is suitable for brushless motor stator production.

It consists of paper inserting machine, end insulation board inserting machine, needle winding machine, stator tester, tracing system and belt conveyor. Operator fill material, each process is completed automatically, automatically transfer the stator to next process. The processing parameter can be set and saved on HMI, and can be called out at any time. It features High intelligent, high automation, high efficiency and low noise.

II.Technical specification:

| Stator OD: | 50-150mm |

| Stator ID: | 30-90mm |

| Stack length: | 20-60mm |

| Winding speed: | Max. 1000RPM |

| Wire diameter: | 0.25-1.1mm |

| Voltage: | 220V±10%, AC (50Hz/60Hz)/ 380V±10%, AC (50Hz/60Hz) |

| Working pressure: | 0.5-0.7Mpa |

| Winding method: | needle winding |

III.MainlyBLDC motor stator machine introduction

The brushless motor stator insulation paper inserting machine

It adopts mechanical driven system, servo system and pneumatic system. As a result, the machine can automatically do positioning, pressing, paper feeding, paper forming, paper pushing. The paper edge can be auto chamfered so as to solve the winding problem caused by paper, and improve the percent of pass of stator. This machine is easy to operate, of high automation, and suitable for series motor, BLDC motor and stepping motor stator.

BLDC insulation board end palte pressing machine

a. Double palm start buttons, operation panel is at the front side of the machine;it is very easy to operate

b. Adapts emergency button, once it has emergency situation, press down this button, machine will stop working immediately, it enhance the safety and reliability;

c. Material conveyor and machine height can be adjusted;In the material conveyor with a cylinder to prevent NG parts into the next process;

d. Add 2 insulation panels to the left and right of the machine.

e. Manual loading, automatic unloading, can be connected to automatic lines.

f. Piston cylinder pressing down stroke is adjustable, helpful for protecting the end plate from bearing too much pressure;

g. There is guiding device, during pressing, there is no axis direction rotation;

h. There is filter pressure reducing valve, pressure is adjustable.

BLDC motor stator needle winding machine

This needle winding machine is suitable for winding BLDC stator. It equips with servo system. It can automatically intert wire end, winding, arraying, indexing, cutting, demolding. This needle winder is designed with two working station. Machine movement is pre-set in the touch screen. All the winding data can be shown on the touch screen during machine running. During running, machine will alarm if something goes wrong.