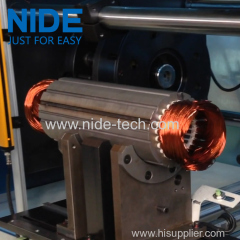

NIDE stator coil forming machine with touch screen

| Min. Order: | 1 Set/Sets |

|---|---|

| Payment Terms: | L/C, T/T |

| Supply Ability: | 100 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | Z3XW2-400-350 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Name: | stator coil forming machine |

| Condition: | new |

| Stator ID: | 80-230mm |

| Stator OD: | ≤350mm |

| Stack Height: | 100mm-400mm |

| Power supply: | 380V 50/60Hz |

| Weight: | about1800kg |

| Dimension: | 2550*1930*2200mm |

| type: | horizontal |

| controlled: | plc |

| Production Capacity: | 100 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 60 days |

Product Description

NIDE horizontal type stator coil forming machine Suitable for Germany with touch screen

(1)Application of the stator coil forming machine

The stator coil final forming machine is applied to deep water pump motor and other various type of overlength motor stator. And it is working after the stator coil lacing machine.

The forming machine is suitable for germany.

(2)Main technical data of the stator coil forming machine

Stator OD: ≤350mm

Stator ID:80-230mm

Stack Height:100mm-400mm

Displacement of Cylinder:30L/min

Power supply:380V 50/60Hz

Weight ≈1800Kg

Dimension:(L)2550*(W)1930*(H)2200mm

(3) Machine mainfunction and characteristic of the stator coil forming machine

This stator coil final forming machine is horizontal type so as to easily load and unload stator.

The final forming machine is driven by hydraulic system, and controlled by PLC.

It expands the inner of the over-hang during forming process; it effectively ensures the over-hang dimension and the appearance.

During tooling change, just change the block, inner expansion core and upper stator fixing sleeve.

The core adopts quick release structure.

For the block and upper stator fixing sleeve, it can be quickly changed by loosening the related screws.

When change different stack stator, loosen related screws, then drive the gear and rack by handle.

After adjustment, tighten the screws.