Automatic stator varnish impregnation plant

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-ZCJW |

|---|---|

| Means of Transport: | Ocean, Land |

| Working position: | 32 |

| Varnish depth: | 160mm |

| Bracket dimension: | 900mm*300mm |

| Working temperature: | less than 145 C, adjustable |

| Productivity: | 4000-5000pcs/20 hours |

| Power: | 75KW (electricity supply);15KW(diesel supply) |

| Machine name: | varnishing machine |

| Machine color: | Customized |

| package: | suitable for sea transportion |

| Condition: | New |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 30 days |

Product Description

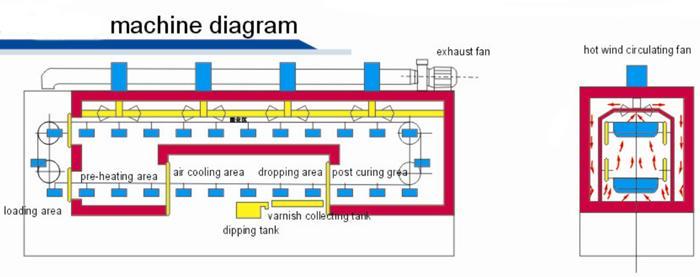

Automatic stator varnish impregnation machine

This type of stator varnish plant is designed to do varnish dipping, impregnation on the stators, starters etc. With a big oven, it can achieve mass production of stators.

(1) Applications:

This machine is suitable for induction motor stator. It is mainly applied to stator winding insulation treatment for fractional horsepower motor and industrial Y series motor which is below frame size 132.

(2) Technical Data

| Working position | 32 |

| Varnish depth | 160mm |

| Bracket dimension | 900mm*300mm |

| Productivity | 4000-5000pcs/20 hours |

| Working temperature | ≤145 C, adjustable |

| Power | 75KW (electricity supply) 15KW (diesel supply) |

| Dimension | 8000mm*2200mm*2500mm (electricity supply) 8000mm*4200mm*2800mm (diesel supply) |

(3) Main features:

The whole process, except for loading and unloading, is completely automatically.

Working process: loading stator to the basket---basket moves to the preheating area---cooling area----dipping area---dropping area----curing area----unloading stators from the basket

Heating time, pitch time and temperature can be set.

This machine is controlled be PLC.

Mass production

Stator suitable for this machine