Segway scooter segway PT winding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 120 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | DCRX1-200 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Voltage: | 220V/50/60Hz |

| Stator diameter: | 80~200mm |

| Stator height: | 18~35mm |

| Wire diameter: | 0.2~1.3mm |

| Winding number: | 1~9 pcs |

| Power: | 1.5KW |

| Weight: | 700Kg |

| Dimension: | 1300*800*1500mm |

| Machine size: | Middle size |

| Color: | Ral9010 or as Per Customer Requirement |

| Production Capacity: | 120 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 55 days |

Product Description

Automatically Wheel motor Segway scooter segway PT stator coil winding machine

Machine description

This wheel hub motor stator coil winding machine equips with servo control system. It can diagnose fault, count output, etc. Other function such as auto winding, multi-diameter wires winding, auto indexing, auto skip slot and winding speed could be programmed in the touch screen. This automatic coil winding machine is easy to operate and maintain.

Technical parameter:

| Wire diameter | 0.3~1.5mm |

| Stator diameter | 90~100mm |

| Slot number | 8~63 |

| Winding number | 1~13 pcs |

| Stator height | 0~50mm |

| Winding speed | 200rpm/min |

| Power supply | 220V/ 50/60Hz 1.5Kw |

| Weight | 900Kg |

| Dimension | 1700*950*2000mm |

Machine structure and working Principle

This automatic stator coil winding machine is consisted of machine body, indexing part, winding and wire array part winding and wire array part wire threading part, tensioner and control system. The winding, arraying and indexing are driven by servo motor controlled by control system

Maintenance

Every day check the mechanical, electrical, pneumatic and lubricating parts before work. Check if the fastener are loosen, abnormal noise in the moving parts or if the electrical parts can work normally.

After work, clean the machine and reset the machine.

Check if there is water in the air source filler regularly. If yes, drain away water.

Check if there is oil in the atomized lubricator regularly. If no, add oil.

Check the lubricating condition of guide way mechanism regularly.

Check the magnet valve screws and its pipe connector every 3 months

Clean the filler every 2 months

Calibrate the pressure gage every 1 year

Segway scooter segway PT winding machine

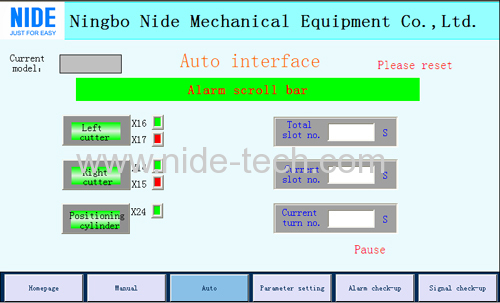

The touch scrren of this scooter winding machine

1) Current model:the current stator model number

2) Total slot no.: the whole stator slot number

3) Current slot no.: the current slot number doing winding

4) Current turn no.: the current turn number doing winding

Stator wound by this machine