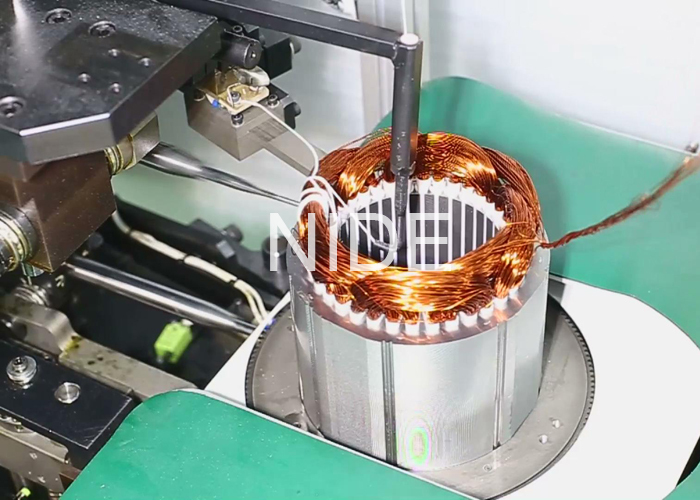

Automatic double side stator coil end lacing machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | BXSIIL1-160-160-6B |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Stack length: | 30~160mm |

| Stator ID: | 30-110mm |

| Max outer diameter of stator: | 190mm |

| Tack time: | 0.4-0.5s/ pin |

| Heights of winding ends(Change cam per 10mm): | 15mm-48mm |

| Over-hang height: | Max. 40mm |

| Sensor: | Omron, Schneider |

| Input: | 380V/50Hz |

| Other components: | Tend, Delixi, Schneider |

| Dimension: | L1500*W650*H1700mm |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transport |

| Delivery Date: | 35 days |

Product Description

This stator coil and lacing machine adopts vertical loading structure, It is equipped with two needles, each needle for laing each side of stator coils. The needle movement is controlled by servo drive system to complete the lacing work. Main spindle speed is adjustable. The lacing type, lacing slot by slot, interval slot lacing and fancy lacing can be set inthe Industrial programmable PLC and HMI. This lacing machine is suitable for lacing multi-species, less yield or more lead wire stator. It has a mature and advanced technology; the machine quality is reliable; and it is easy to operate and maintain.

Applications:

This machine is appropriate for micro induction motor like conditioner motor, washer motor, compressor motor, fan motor, alternator motor, pump motor etc.

Lacing machine technical data

| Item | Unit | Data |

| Size | mm | 1400(L)×580(W)×1600(H) |

| Weight | kg | ≤750kg |

| Power | 380V/50Hz three phase four wire power | |

| Working pitch time | S/PC | ≤14(24 Slots) |

| ID | mm | Φ40~Φ120 |

| OD | mm | Φ160 |

| Head coil height | mm | 50 |

| Tooling stroke | mm | ≤70 |

| Lacing speed | s/s | 0.8 |

| Air source | Mpa | 0.4~0.8 |

Competitive advantages:

Fast speed , low noise; simple operation and easy tooling change, double sides lacing simultaneously. PLC and touch screen control, it's programmable.

Operation step

Connect lacing machine to power source and air source. Do threading.

Put the stator in the tooling.

Switch to "auto" mode. Then press "start" button by two hands.

Machine will automatically do the lacing process.

Stator after doing lacing

The lacing process