Semi-auto High Precision armature coil winding machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-ZB-2GB |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Spindle length: | 170mm |

| Wire diameter: | 0.1~1.08mm |

| Per-set Turns: | 0-9999 |

| Advance Turns: | 0-9 |

| Rotation Speed: | 0-1400r/min |

| Armature diameter: | ≤60mm |

| Stack length: | ≤100mm |

| Spindle motor power: | 0.75KW |

| Power Supply Voltage: | 220V±10% 50Hz |

| Air source pressure: | 0.5~0.7MPa |

| Production Capacity: | 30 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 35 days |

Product Description

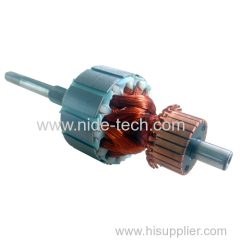

High Precision armature coil winding machine / Rotor Wire Winder Machine

Description:

Double flyer Armature Wire Winding Machine is used for even number slot motor wire winding. The rotor winder equipment adopts Japanese frequency speed adjustment, low rise and accelerating, numeric code dialing setting operation speed and deceleration speed ahead, breaking and location accurate, foot stepping to loose tooling, automatic closing tooling. The armauture coil winding machine is Easy operating, and the armature winding machine can save more labor.

Main technical data:

| Power suply Voltage | 220V±10%, 50HZ |

| Power | 0.8KW |

| Pre-set turns | 0-9999 |

| Advance Turns | 0-9 |

| Principal Axis Center Height | 170mm |

| Rotation Speed | 0-1400r/min |

| Wire Diameter | 0.08-1.08mm |

| controlled | PLC |

Competitive advantages

Variety of application, easy operation.

We have Overseas Service Center.

Machine is controlled by PLC. All the parameter can be set in the touch screen.

The armature winding machine is suitable for stators with different model number and dimension.

The operation and tooling change process is easy.

We could customize machine for our customer as per their requirement.

We directly supply our machines to many countries, like USA, France, Turkey, Iran, India, Brazil, Argentina, Mexico etc.

Information needed for Armature Winding Machine inquiry

It will be better if customer could send us detailed drawing including below information.

1. Rotor lamination drawing

2. Rotor assemble drawing

3. Rotor stack drawing

4. Rotor winding diagram drawing: with rotor wire diameter and turn number

5. Commutator drawing

6. Required productivity

7. Other technical requirement

If possible, it will be better if customer can send us samples.

High Precision armature coil winding machine / Rotor Wire Winder Machine