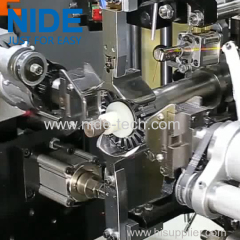

Automatic Armature Double Flyer Copper Wire Winding Machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 40 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | ND-LAW-5B4 |

|---|---|

| Means of Transport: | Ocean |

| Wire diameter range: | 0.16~0.55 mm |

| Armature diameter: | 20~60 mm |

| Stack length: | 10~70 mm |

| Shaft diameter: | 3~15 mm |

| Commutator diameter: | 8~40 mm |

| Winding speed: | 0~2500 rpm |

| Shaft length: | less than 250mm |

| Armature Slot: | even slot |

| Production Efficiency: | 22S/PC |

| Power source: | Three phase AC380V 50/60Hz |

| Production Capacity: | 40 sets |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 35 days |

Product Description

PLC controlled Semi-auto Armature rotor Double Flyer Winding Machine

Quick Detail of the

1. This armature rotor coil winding machine has two winding flyers.

2. The winder equipment can automatically winding coil .

3. This coil winder machine is suitable for wire diameter range 0.08-1.08mm

4. This coil winding machine is suitable for both riser and hook type commutator.

Description:

Semi-auto Double flyer Armature Winding Machine is especially designed for winding even slot armatures. It's suitable for hook or riser type commutator armature. It is widely used in many armatures field like automobile motor, motorcycle motor, house appliances series excited motor, power tool motor and various kinds of PMDC micro motor. It's an economic, fast and reliable specialized winding machine.

Working principle

1. This winding machine adapts double flyers structure, 1set 1KW servo motor drive the two flyers rotation, and 400W indexing servo motor. During working, the armature is clamped tightly by two nos winding tooling and clamping device. When flyers are running, wire goes through the wire holder, tension device then enters hollow spindle, comes out from wire sliding wheel, then the wire slides into the armature slot through flyer wire guiding wheel. After this step, put armature into the slot to do winding.

2. This machine adapts servo system to do winding. Meanwhile, machine action is controlled by true color human-machine PLC controller; armature indexing is controlled by big power stepping motor; servo speed is controlled by double flyers rotation speed. Moreover, this machine has other functions, such as slow increasing speed when starting, Max. speed limit, brake time, CW &CCW rotation, counting pre-set, etc. With complete function and reliable running, this machine is convenient for operation.

3. The machine fixture is controlled by pneumatic cylinder, high performance with low cost. It's equipped with working plate, to operating more convenient.

4. The machine adapts PLC system pulse counting signal, whose correctness is 100%.

Main technical data of rotor winding machine:

1. Input voltage: 220V±10%

2. Rated frequency: 50Hz

3. Motor power: 2.0KW 1500r/min

4. Spindle speed: 0~1500r/min

5. Center height: 160mm(it can be customized.)

6. Max.armature OD: f60mm(it can be customized.)

7. Pre-setting turn number range: 0~32767

8. Display: true color touch screen

9. Speed adjustment: controlled by touch screen

10. Starting method: manual switch

11. Max. speed: 4000r/min

12. Acceleration time: settable freely(default value is 100-500MS)

Rotor winding machine

This rotor winding machine has mechanical arm.