Automobile industrial stainless steel deep groove ball bearings

| Min. Order: | 10000 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 1000000 |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | NDPJ-ZC-1600 |

|---|---|

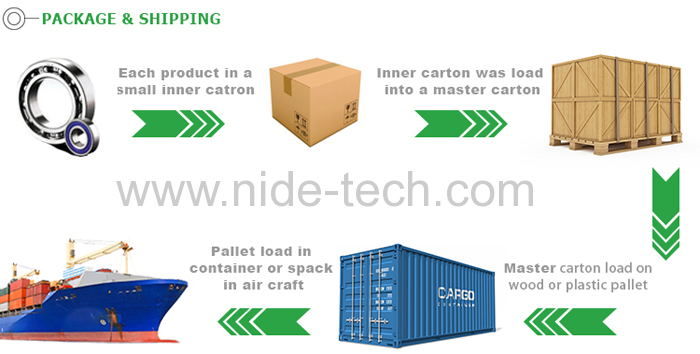

| Means of Transport: | Ocean, Air, Land |

| Material Type: | Steel Gcr 15 |

| Dimension: | Customized |

| Composition: | Two Rings, Rolling Elements and a Cage |

| Seal Type: | Rubber or Iron |

| Grease Type: | SRL or Customized |

| Certifiacate: | CCC |

| Condition: | New |

| Vibration Grade: | Customized |

| Model no.: | NDPJ-CZ03 |

| Package: | Pallet |

| Production Capacity: | 1000000 |

| Packing: | suitable for sea transport |

| Delivery Date: | 20 days |

Product Description

Nide team could manufacture ball bearing as per customer's drawing and samples. If customer only has samples, we could also design drawing for our customer. We also provide customized service.

Ball bearing vibration is closely related to bearing noise. During the ball bearing manufacturing & inspection, bearing noise can be controlled through strict control on the vibration. During bearing manufacturing, a frequency spectrum analyzer is used to measure the magnitude of vibration and the distribution of the frequency. When the rotating speed bearing reaches1800rpm, the frequency between 50~10000HZ could be divided into three bands.

Manufacturing

| Incoming inspection | |

| Outer ring | Inner ring |

| Heat treat | |

| Face grinding | O.D. Grinding |

| O.D. Grinding | Face grinding |

| Raceway grinding | |

| \ | Bore grinding |

| Hone raceway | |

| Wash/Clean | |

| Classification | |

| Cage insertion | |

| Washing | |

| Lubricant insertion | |

| Seal insertion | |

| Noise testing | |

| Packing | |

Competitive advantages

1. Our ball bearing has a wide application, such as automotive industry, household appliances, power tools and etc.

2. We directly supply our ball bearing to many countries, like USA, France, Turkey, Iran, India, Brazil, Argentina, Mexico etc.

3. We have a wide range of ball bearing.

4. We could customize ball bearing for our customer.

Information needed for ball bearing inquiry

It will be better if customer could send us detailed drawing including below information.

1.Ball bearing model number

2. Ball bearing dimension

3. Ball bearing application

4. Required quantity

5. Other technical requirement.