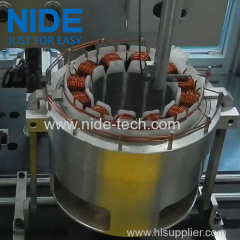

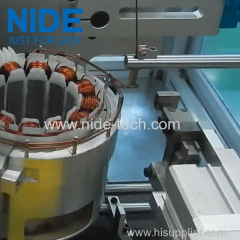

Automatic BLDC MOTOR STATOR WINDING MACHINE for brushless motor coil winding

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 20 Pieces |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | NXN1-100-150 |

|---|---|

| Means of Transport: | Ocean |

| Wire diameter: | 0.08~1.2mm |

| Min. stator ID: | 6mm |

| Max. stator OD: | 260mm |

| Max. winding speed: | 600RPM |

| Cycle time: | About 4~4.5mins/2pcs |

| Max. stator stack length: | 120mm |

| Power: | Single phase 220V, 50/60Hz |

| Air pressure: | 6kg/cm2 |

| Machine dimension: | W850*L1000*H1600mm |

| Weight: | About 500kg |

| Production Capacity: | 20 Pieces |

| Packing: | Wooden case which is suitable for sea transportation |

| Delivery Date: | 60 days |

Product Description

Features:

1.Double stations, The BLDC stator coil needle winding machine could be designed for four stations.

2.During high speed winding, the bldc winding process can be controlled, The needling winding machine automatically complete winding,

3.indexing, hanging wire, hanging the wire head and wire end and cutting wire.

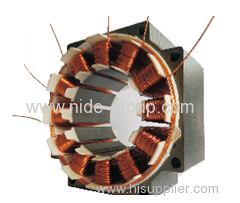

Application: Suitable for BLDC motor stator winding, such as stepping motor, brushless motor, fan motor, bladeless fan motor, servo motor, etc.

Technical specification:

Item | Specification |

Wire diameter: | 0.08~1.2mm |

Min. stator ID | 6mm |

Max. stator OD | Two sations-260mm, Four stations-120mm |

Max. winding speed | 600RPM; For 1.0mm wire, the winding speed is about 200~260RPM; 0.15~0.45mm wire: winding speed is adjustable within 0~450RPM; 0.45~1.0mm wire: winding speed is adjustable within 0~300RPM;

|

Cycle time | For 1.0mm diameter wire 39turns 12slots stator, about 4~4.5mins/2pcs |

Max stator stack length | 120mm |

Power supply | single phase 220V, 50/60Hz |

Air pressure | 6kg/cm2 |

Machine dimension | W850*L1000*H1600mm |

Weight | About 500kg |

Operating procedures

1. Power on the BLDC winding machine

2. Thread the wire

3. Put stator to the working station table

4. Adjust the tooling according to different model stator

5. Set the stator diameter in the touch screen then select the pre-set data.

6. Press "start" button.

7. The needle winding Machine will automatically do winding.

8. Take out the stator