Eight working station coil winding machine automatically

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,FCA,EXW |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10 sets |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Model No.: | RXL3-100 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Model no.: | RXL3-100 |

| Wire diameter: | 0.19-1.2mm |

| Swing diameter: | 220mm |

| Operation station: | 8 |

| Winding head: | 4 |

| Max Thickness of stator lamination: | 100mm |

| Max Stator ID: | 160mm |

| Max RPM: | 2500RPM |

| Air source: | 0.4Mpa |

| Power supply: | 380V- 50/60HZ |

| Production Capacity: | 10 sets |

| Packing: | Wooden case which is suitable for sea transport |

| Delivery Date: | 45 days |

Product Description

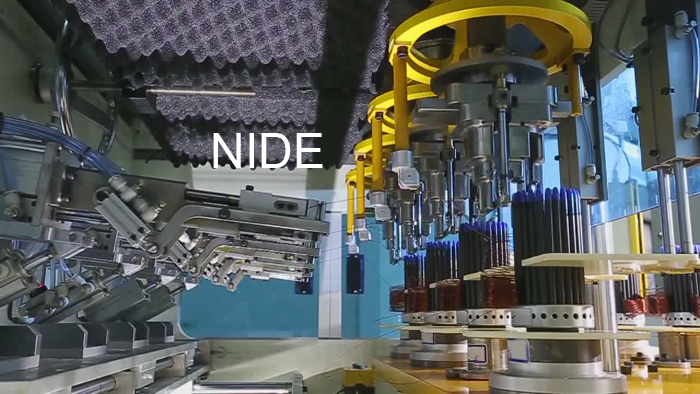

Eight working station coil winding machine

1.Machine features of stator coil winding machine

The coil winding machine is four winding heads with eight operation stations, high efficiency is its feature.The coiling winder machine automatically put the coil into the transfer former orderly, especially suitable for high production capacity requirement,high slot filling rate,small slot opening stator coil winding. Winding mode such as auto skip,auto cutting and auto indexing could be completed at a time successively; parameter could be set in human-machine interface, continuous/discontinuous winding way and meets the 2 poles, 4 poles and 6 poles coils winding,

2.Specification of stator coil winding machine

| name. | RXL3-100 8 working stations stator coil winding machine |

| Wire diameter | 0.19-1.2mm |

| Swing diameter | 220mm |

| Operation station | 8 |

| Winding head | 4 |

| Max Thickness of stator lamination | 100mm |

| Max Stator ID | 160mm |

| Max RPM | 2500rpm |

| Air source | 0.4mpa |

| Power supply | 380V- 50/60HZ |

3.Application of stator coil winding machine

This machine is suitable for 2 poles. 4 poles, 6 poles coils winding.

4.Operator step of stator coil winding machine

1.Power on the machine

2.Thread wire this this motor

3. Set the winding parameter in the touch screen

4. Press the "start" button

5. Machine will do winding process automatically

6.After finishing the winding, machine will stop

7.Take out the wire from the tooling.

Information needed for Automatic Stator Coil Winding Machine inquiry

It will be better if customer could send us detailed drawing including below information.

1. Stator drawing

2. Stator winding drawing

3. Winding distribution drawing

4. Other technical requirement

If possible, it will be better if customer can send us samples.

Eight working station coil winding machine

This stator winding machine has 8 winding station, all the four heads will do winding together. Stator coil winding machine

Machine partial picture: all the wire will be wound into the winding form. It will be easier to transfer to the stator..