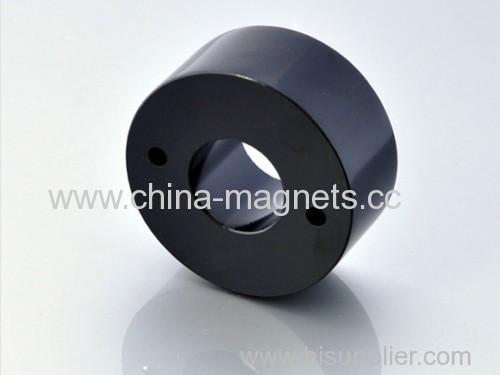

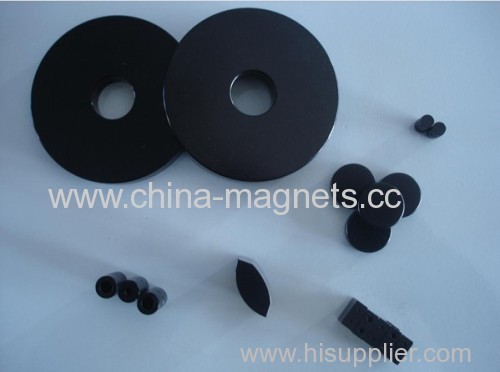

Ring magets with epoxy plating

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | Ring magets with epoxy plating, L/C, T/T |

| Supply Ability: | 100 tons per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | China Manufacturer And Exporter With Gold Plated Rare Earth Neodymium Magnets, Supplier Sintered Neodymium (NdFeB) Rare Earth Magnets Grade N33 N35 N38 N40 N42 N45 N48 N50 N52(M H SH EH UH AH), Supplier Neodymium Supermagneti Permanent Magnets For Sale, China Manufacturer And Exporter Name Badge Magnets With Tow Pieces Magnet On The Iron Plates, Supplier Neodymium Rare Earth Block Magnets Size 0.5X0.375X0.125 |

Product Detail

| Means of Transport: | Ring magets with epoxy plating, Ocean, Air |

|---|---|

| Application: | Industrial Magnet |

| Shape: | Disc |

| Type: | Permanent |

| Composite: | Rare Earth Magnet |

| Brand Name: | Xionghai |

| Plating: | Epoxy |

| Grade: | N33 N35 N38 N40 N42 N45 N48 N50 N52(M H SH EH UH AH) |

| Shape: | Disc, Ring |

| Production Capacity: | 100 tons per month |

| Packing: | Neutral packing |

| Delivery Date: | 15days |

Product Description

Xionghai Ring magets with epoxy plating for sale.Neodymium Magnet, Sintered NdFeB magnet, the third generation of rare-earth permanent magnet, is the most powerful and advanced commercialized permanent magnet up to date. Neodymium Magnet has high coercive force, high energy and high performance/ cost ratio. It can be formed into various sizes and widely used in many fields such as aviation, electronics, instruments, meters, machines and medical instrument.

The Magnetic Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

Magnetic Properties of Sintered NdFeB Permanent Magnets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pictures of Ring magets with epoxy plating/ Sintered NdFeB magnet / Neodymium Iron Boron Magnet / Sehr Starke Magnete: