Buy china magnet with sintered Neodymium Magnets

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T, Neodymium Magnets |

| Supply Ability: | 100 tons per month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | Ningbo, Zhejiang, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | China Manufacturer And Exporter With Gold Plated Rare Earth Neodymium Magnets, Supplier Sintered Neodymium (NdFeB) Rare Earth Magnets Grade N33 N35 N38 N40 N42 N45 N48 N50 N52(M H SH EH UH AH), Supplier Neodymium Supermagneti Permanent Magnets For Sale, China Manufacturer And Exporter Name Badge Magnets With Tow Pieces Magnet On The Iron Plates, Supplier Neodymium Rare Earth Block Magnets Size 0.5X0.375X0.125 |

Product Detail

| Model No.: | Xionghai magnets |

|---|---|

| Means of Transport: | Ocean, Neodymium Magnets, Land |

| Application: | Industrial Magnet |

| Shape: | Others |

| Type: | Permanent |

| Composite: | Neodymium Magnet |

| Brand Name: | Xionghai Magnets |

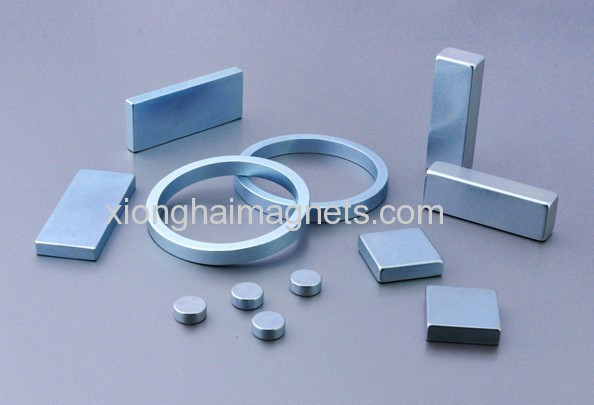

| Shape: | Disc, Ring, Cylinder, Block,Irregular,Arc Segment |

| Grade: | N33 N35 N38 N40 N42 N45 N48 N50 N52(M H SH EH UH AH) |

| Plating: | Ni-Cu-Ni,Zn,Epoxy,Gold,and etc. |

| Neodymium Magnets: | Neodymium Magnets |

| Production Capacity: | 100 tons per month |

| Packing: | Neutral packing |

| Delivery Date: | 15days |

Product Description

Xionghai Neodymium Magnets preparesits anisotropic powders by either casting an alloy melt into a mold, or strip casing. Strip Casting offers the advantage of better chemical stability. Subsequently, the ingot from the mold or the flakes from Strip Casting are pulverized to a uniform grain/particle size. The best method for obtaining the desired grain size is by HDDR. The HDDR [hydrogenation-decomposition-desorption-recombination] process yields a more homogenous particle size with a minimum of α-Fe, and Nd-rich phases. Anisotropic Nd-Fe-B, HDDR powders prepared from strip cast alloys are used for the HAST [Highly Accelerated Stress Test] grades of NdFeB Magnets, including N, H, SH, UH, EH, and AH grades.

Improved Corrosion Resistance:

The HAST protocol used on our neodymium iron boron magnets can qualitatively reflect the service life of the magnet. This test exposes the magnet to 130°C, 95% RH, at 2 ATM for more than one day. The magnet is massed before and after the test. Our magnets measure a weight loss of less than 5 mg/cm2.

High Maximum Working Temperature:

Our AH series of NdFeB magnets have working temperatures up to 240°C.

Applications: sensors, motors, rotors, wind turbine,wind generators, loudspeakers, magnetic hooks, filters automobiles, Toys, micro-special electric machinery, audio equipments, electronic industry, auto industry, magnetic transmission gears and magnet therapy equipment, sorption, ads, teaching tools and other office automation, magnet toys, aero generators, magnetic toys, magnetic separators, magnetic bracelets, magnetic necklaces, copiers, synchrotrons, radiation sources, free electron lasers, agriculture, detection earthquake, and so on.

The Physical Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

| Parameters | Units | Indicators |

| Density | g/cm³ | ≥7.3 |

| Home temperature | ℃ | 310-340 |

| BrReversible temperature coefficient | ℃/% | -0.100~-0.130 |

| HcjReversible temperature coefficient | ℃/% | 0.40~0.70 |

| Compressive strength | N/mm2 | 1050 |

| Bending strength | N/mm2 | 250 |

| Tensile strength | N/mm2 | 80 |

| Webster Hardness | 600 | |

| Coefficient of thermal expansion(20 to 200℃) | 10-6/k | ∥5⊥-1.5 |

| Specific heat | J/(Kg.K) | 460 |

| Thermal conductivity | W/(m.K) | 9 |

| Resistivity | μΩ.cm | 150 |

The Magnetic Properties of Neodymium Permanent Magnete Super Strong Magneti Neodimio Rare Earth Aimant Neodyme:

Magnetic Properties of Sintered NdFeBMagnets | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pictures of Neodymium Magnet / Sintered NdFeB magnet / Neodymium Iron Boron Magnet / Sehr Starke Magnete: