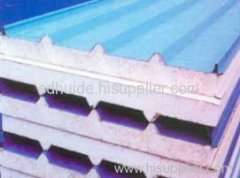

color sandwich panels

| Min. Order: | 1000 Piece/Pieces |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 10,000 square meter |

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

| Main Products: | Hot Dipped Galvanized Steel Coils, PU Sandwich Roof Panel, Cold Rolled Steel Coil, Pre-painted Galvanized Steel, Sandwich Panel |

Product Detail

| Model No.: | HD4 |

|---|---|

| Means of Transport: | Ocean |

| Brand Name: | SDHUIDE |

| type: | EPS,ROCK WOOL |

| color: | sea blue,white grey,RAL or as customers' sample |

| thickness: | 3cm-15cm |

| width: | as the customers' request |

| length: | as the customers' request |

| Production Capacity: | 10,000 square meter |

| Packing: | the standard export package or as customers' request |

| Delivery Date: | 30 days after received the 30% deposit |

Product Description

INTRODUCTION

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. The production line is mainly applied to make wall panels of steel structure and roof panels, being also able to make various other insulation panels if replacing facing sheet. Its operation principle is as follows: Rigid polyfoam raw materials, according to a certain blending ratio, are delivered into mixing head to agitate through metering pump unit on the injection machine and then uniformly injected onto the bottom facing sheet of sandwich panel. After the injection the bottom facing sheet shall move toward the double-belt conveyors together with panel's top facing sheet. Between the two conveyors, injected raw material is foamed and hardened into shape. At the end of the line, the formed sandwich panel is cut into preset length by an automatic tracking cutter.

The production line has already passed the hi- and neo-tech product identification carried out Jiangsu Economic and Trade Commission and Jiangsu Science and Technology Department, being listed as a main nation-level new product and evaluated as one of the first-batch high and new products of Jiangsu Province in the year of 2004(Product No.: 041111G0025N).

Main technical parameters

Reciprocating times of injection head per minute more than 60

Production line speed 1~4 m/min

Laminating length of the laminator 18 m

Maximum temperature of hot-air circulating 70 degree

Maximum rising height of the top conveyor 250 mm

The total capacity for the production line 85~125 kw

The continuous production line for rigid polyfoam laminated panel with color steel facings is a kind of specialized equipment used for producing color-steel sided sandwich panels with the middle layer of anti-combustion polyurethane, polyisocyanurate or phenolic foam plastic. The thickness of the produced sandwich panel ranges from 0 to 10 mm, the width between 750 to 1000 mm and the length on request. The production line is mainly applied to make wall panels of steel structure and roof panels, being also able to make various other insulation panels if replacing facing sheet. Its operation principle is as follows: Rigid polyfoam raw materials, according to a certain blending ratio, are delivered into mixing head to agitate through metering pump unit on the injection machine and then uniformly injected onto the bottom facing sheet of sandwich panel. After the injection the bottom facing sheet shall move toward the double-belt conveyors together with panel's top facing sheet. Between the two conveyors, injected raw material is foamed and hardened into shape. At the end of the line, the formed sandwich panel is cut into preset length by an automatic tracking cutter.

The production line has already passed the hi- and neo-tech product identification carried out Jiangsu Economic and Trade Commission and Jiangsu Science and Technology Department, being listed as a main nation-level new product and evaluated as one of the first-batch high and new products of Jiangsu Province in the year of 2004(Product No.: 041111G0025N).

Main technical parameters

Reciprocating times of injection head per minute more than 60

Production line speed 1~4 m/min

Laminating length of the laminator 18 m

Maximum temperature of hot-air circulating 70 degree

Maximum rising height of the top conveyor 250 mm

The total capacity for the production line 85~125 kw