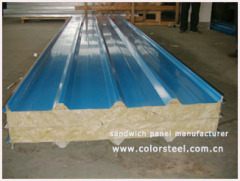

Eps Sandwich panel

10.0~20.0 USD

| Payment Terms: | TT OR LC |

|---|---|

| Place of Origin: | Shandong |

Company Profile

| Location: | Binzhou, Shandong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company, Agent |

| Main Products: | Hot Dipped Galvanized Steel Coils, PU Sandwich Roof Panel, Cold Rolled Steel Coil, Pre-painted Galvanized Steel, Sandwich Panel |

Product Detail

| Model No.: | HD07 |

|---|

Product Description

1.According to core material kinds, the sandwich panel includes in Polyurethane (PU), polystyrene (EPS) and rock wool or glass wool sandwich panel, the up & down plate is galvanized steel sheet, prepainted steel sheet, aluminum sheet or pressboard sheet. It is widely used as wall or roof form cold storage, industrial workshop and public building etc.

2.Features:

1), This kind of sheets is composed of three layers upper and lower layer of colored steel sheet and an intermediate layer of polyurethane foam. Supplied in roll, it normally used as wall and roof of building.

2), The sheet has good performance of thermal insulation and sound insulation, and meets B1 the requirement on fire protection.

3), As the load is jointly borne by the three layers, the sheet has high strength and rigidity; besides, the lower player surface is flat and smooth with clear lines, which makes it look beautiful and clean.

4), In use of such wall face sheets, wall beams can be cancelled partially or wholly according to spanning size.

5). The weight is light, easy to transport, easy to install.

Extruded plastic polystyrene sandwich panel is combined by extruded plastic foam and the professional glue water stick to the metal sheet, make these two kinds of material work in phrase, and satisfy some requirement for some function. As a new type architectural energy save and environment protect material, they can widely use in the civil house, commercial architecture, industry factory and the important big project, etc.

Characteristics: As the heat reserve and heat insulate roof material, extruded plastic polystyrene sandwich panel has the following advantages in manufacture, installation, use, repair and prevent leaking:

2.Features:

1), This kind of sheets is composed of three layers upper and lower layer of colored steel sheet and an intermediate layer of polyurethane foam. Supplied in roll, it normally used as wall and roof of building.

2), The sheet has good performance of thermal insulation and sound insulation, and meets B1 the requirement on fire protection.

3), As the load is jointly borne by the three layers, the sheet has high strength and rigidity; besides, the lower player surface is flat and smooth with clear lines, which makes it look beautiful and clean.

4), In use of such wall face sheets, wall beams can be cancelled partially or wholly according to spanning size.

5). The weight is light, easy to transport, easy to install.

Extruded plastic polystyrene sandwich panel is combined by extruded plastic foam and the professional glue water stick to the metal sheet, make these two kinds of material work in phrase, and satisfy some requirement for some function. As a new type architectural energy save and environment protect material, they can widely use in the civil house, commercial architecture, industry factory and the important big project, etc.

Characteristics: As the heat reserve and heat insulate roof material, extruded plastic polystyrene sandwich panel has the following advantages in manufacture, installation, use, repair and prevent leaking:

.jpg)