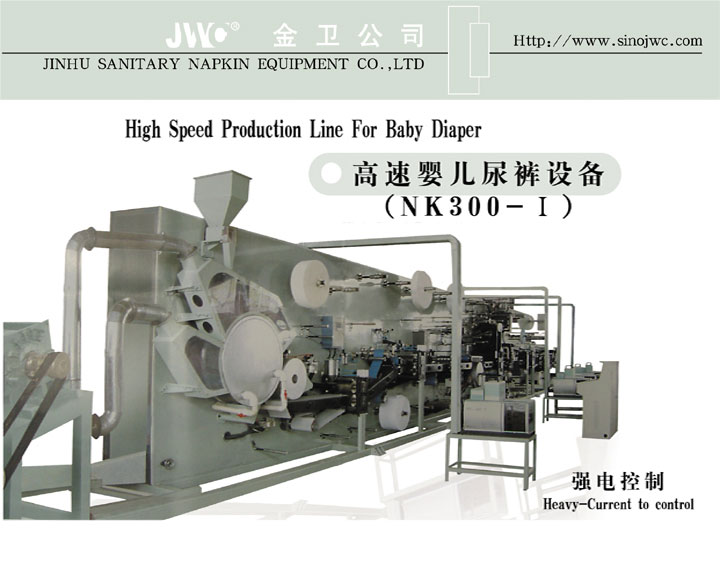

Baby Diaper Production Lines

| Place of Origin: | Fujian |

|---|

Company Profile

| Location: | Quanzhou, Fujian, China (Mainland) |

|---|

Product Detail

| Model No.: | PX-YKJ-150B |

|---|

Product Description

Function & Assemble Parts:

1. It can produce four specifications (L,M,S,XL) of products by exchanging

cutting tool and simple regulation. After molding, products are

tri-folded into square type and output after being vertically arranged.

2. It can be adopted with programmable controller to materialize auto

monitoring production procedure, embossment roller temperature,

production speed and so on.

3. Automatically catch hydrophobic N.W. fabric, guide-flow N.W. fabric,

hydrophilic N.W. fabric, PE film; without stopping, auto exchange

material, control tension rectification and get rid of wasted products.

4. Touching screen and man-machine interaction are installed to auto

display production breakdown and parameter.

5. Teeth-like crusher can take treated or untreated rolled pulp.

Structure & Character:

1. Driving system consists of gearwheel device, universal shaft couplings

and arc-gear synchronous belt, driving components are installed on

the backboard of equipment with high driving accuracy and low

mechanical consumption.

2. Large-diameter web wheel lay out pulp to guarantee even thickness of

cotton core under high-speed operation with adjustable amount of SAP.

3. Programmable controller, man-machine interface and frequency converter

are of Japanese "Mitsubishi" brand.

4. Conducting ring, pipe heater, bearing, synchronous belt, conveyance

belt and so on are of import brands.

5. Main press-cut rollers adopt universal shaft driving . The driving

is fast and it can guarantee the knives' service life.

Main Technical Parameter:

1. Designed production speed:450PCS/min

2. Stable production speed: 300~350 PCS/min

3. Machine power:160kw (380v 50Hz) (include glue applicators.)

4. Overall size of equipment (L x W x H m): 24 x 2.6 x 3.2 (Exclude crusher)

5. Weight of equipment: about 30t

1. It can produce four specifications (L,M,S,XL) of products by exchanging

cutting tool and simple regulation. After molding, products are

tri-folded into square type and output after being vertically arranged.

2. It can be adopted with programmable controller to materialize auto

monitoring production procedure, embossment roller temperature,

production speed and so on.

3. Automatically catch hydrophobic N.W. fabric, guide-flow N.W. fabric,

hydrophilic N.W. fabric, PE film; without stopping, auto exchange

material, control tension rectification and get rid of wasted products.

4. Touching screen and man-machine interaction are installed to auto

display production breakdown and parameter.

5. Teeth-like crusher can take treated or untreated rolled pulp.

Structure & Character:

1. Driving system consists of gearwheel device, universal shaft couplings

and arc-gear synchronous belt, driving components are installed on

the backboard of equipment with high driving accuracy and low

mechanical consumption.

2. Large-diameter web wheel lay out pulp to guarantee even thickness of

cotton core under high-speed operation with adjustable amount of SAP.

3. Programmable controller, man-machine interface and frequency converter

are of Japanese "Mitsubishi" brand.

4. Conducting ring, pipe heater, bearing, synchronous belt, conveyance

belt and so on are of import brands.

5. Main press-cut rollers adopt universal shaft driving . The driving

is fast and it can guarantee the knives' service life.

Main Technical Parameter:

1. Designed production speed:450PCS/min

2. Stable production speed: 300~350 PCS/min

3. Machine power:160kw (380v 50Hz) (include glue applicators.)

4. Overall size of equipment (L x W x H m): 24 x 2.6 x 3.2 (Exclude crusher)

5. Weight of equipment: about 30t