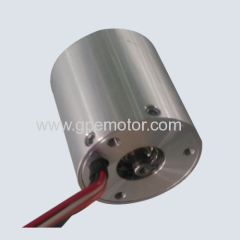

Coffee Machine Motor

| Min. Order: | 10000 pcs |

|---|---|

| Place of Origin: | Guangdong |

Company Profile

| Location: | Shenzhen, Guangdong, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

Product Detail

| Model No.: | FS-5412H |

|---|---|

| Brand Name: | Chebgfang motor |

| Dimension: | dia. 37.8 x 31.5 Thk. x 53 L. shaft O.D. 3.175 mm |

| Delivery Date: | less than 30 days |

Product Description

The models we list below are part of our existing designs. We offer specific motor design for every customer.

|

Model No.

|

Main Performance

|

|||||||||

|

Rated Voltage

|

No Load

|

At Maximum Efficiency

|

At Stall

|

|||||||

|

Speed

|

Current

|

Speed

|

Current

|

Torque

|

Output

|

Eff.

|

Current

|

Torque

|

||

|

V

|

r/min

|

A

|

r/min

|

A

|

g.cm

|

W

|

%

|

A

|

g.cm

|

|

|

FS-5412SH-11160R

|

100 VAC*

|

9,000

|

0.10

|

6,886

|

0.33

|

357

|

25.2

|

60.18

|

1.08

|

1520

|

|

FS-5412SH-10188

|

120 VAC*

|

12,000

|

0.06

|

9,100

|

0.31

|

300

|

28

|

55

|

1.0

|

1250

|

*: AC full wave rectifying

Unit Conversion: 1g.cm≈0.098mN.m≈0.014oz.in 1mm=0.039in 1g=0.035oz

- Coffee Machine Motor

- Sweeper motor

- HVDC motor

- Dimension: φ 37.8 x 31.5 Thk. x 53 L. shaft O.D. 3.175 mm

- Basic Structure: SECD housing / SECC end cap

- Application: Sweeper / Coffee maker

- Weight: Approx. 180g

|

Basic Structure of Chengfang Motors

↓

↓

↓

↓

↓

|

Customerized Options

|