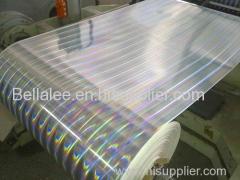

holographic foil

| Min. Order: | 7680 Square Meter |

|---|---|

| Payment Terms: | LC, T/T |

| Supply Ability: | 16,000,000 sqm/month |

| Place of Origin: | Zhejiang |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | SEA |

|---|---|

| Method: | Heat Transfer Printing |

| Usage: | Bag |

| Brand Name: | HENGFENG |

| Production Capacity: | 16,000,000 sqm/month |

| Packing: | 10 rolls/ carton |

| Delivery Date: | 10~15days |

Product Description

Hot stamping foil is usually made up of a film carrier, a release layer, a lacquer layer, a metallization layer, and an adhesive layer. During stamping a heated stamping wheel or engraved stamping die activates the very thin lacquer layers by means of heat and pressure, which causes the lacquer layers to bond permanently with the substrate of plastic, paper, etc. The film carrier is then peeled off . If it's pigmented hot stamping foil or holographic foil, there exist some minor differences: a. no metallization layer for pigmented foil; b. one more process for holographic foil, namely, mould pressing.

Fields of application:

Cigarette packages, cosmetic carton, packaging of confectionary and wine, book covers, greeting cards, sheet labels, stickers, advertising material, etc.

Cigarette packages, cosmetic carton, packaging of confectionary and wine, book covers, greeting cards, sheet labels, stickers, advertising material, etc.

Specification:

Standard size: 0.64m (width) X 120m (length) / roll (customization is available)

Inner Core: 1"/3

Standard size: 0.64m (width) X 120m (length) / roll (customization is available)

Inner Core: 1"/3

Packing:

Interior: each roll packed with plastic film

Exterior: packed with carton box (10 rolls/carton)

Interior: each roll packed with plastic film

Exterior: packed with carton box (10 rolls/carton)

Tips: The success of the stamping depends on the combined performance of the component that comprise it-the hot stamping foil, the adhesive, the printing method and the substrate used. Therefore, we suggest that a sample be requested prior to the purchase order.

.jpg)