ceramic fiber

4.53 USD

| Min. Order: | 1 Piece/Pieces |

|---|---|

| Payment Terms: | T/T |

| Supply Ability: | 100000kg |

| Place of Origin: | Henan |

Company Profile

| Location: | China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

| Main Products: | Alumina Crucibles, Molybdenum Electrode, Silicon Carbide Heater, Alumina Ceramic Crucible, Ceramic Fiber Blanket |

Product Detail

| Model No.: | CF7000 |

|---|---|

| Means of Transport: | by sea/air |

| ceramic fiber: | furnace heating elemenst |

| Production Capacity: | 100000kg |

| Packing: | as the buyers' option |

| Delivery Date: | 1-35days |

Product Description

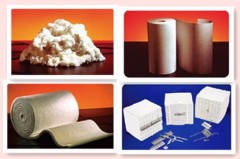

Jinyu ceramic fiber include ceramic fiber blanket, ceramic fiber board, ceramic fiber heater, tube, block, AC Vacuum Shaped Products & Electric Heating Module, and various ceramic fiber non-conventional products. The product is featured with low thermal conductivity and sound heat insulation. Zirconia coated ceramic setter is another main product of our company, mainly used for the agglomeration of various electronic ceramics. Zirconia coating could prevent reaction and adhesion between electronic ceramics and the setter, hence to ensure excellent performance of the sinter product.

Ceramic Fiber Board and Vacuum Shaped Products are made by different fire-resistant fibers, non-organic and few organic adhesive mixed in different percentages. The use temperature of these products can be varied from 1000℃ to 1800℃.

Ceramic fiber module is made of blanket fan folded, or pre-cut blanket stack bonded to form a module, to form a module with cut edges exposed. ceramic fiber including standard ceramic fiber, high pure ceramic fiber, high Aluminum ceramic fiber, Zirconium ceramic fiber.

Ceramic industry: kiln liner, kiln car

Glass industry

Piping heat insulation, common heat resisting material

Other high temperature insulation

Heat preservation materials as the back lines for the kilns in the field of ceramic

Heat preservation materials as the wall lines and back lines for the kilns in the field of metallurgy and petrochemical industry

Heat preservation materials as the wall lines and back lines for the Glass furnace.

Refractory and insulating materials for heat treatment equipment

The back lines of refractory brick for electrolytic reducing bath in aluminum factory

Materials of the wall lines and back lines of heat and pyroreaction equipment

Jinyu Ceramic Fiber Insulated Heaters produce fast, efficient, and reliable uniform heat to temperatures of 700-1150 C.

These heaters are comprised of high quality helically wound Fe-Cr-Al alloy resistance wire elements embedded in a rigid body of vacuum-formed high temperature refractory fiber. This ceramic fiber insulation has very low weight, thermal mass and thermal conductivity and thus can handle extremely rapid cycling.

The elements are typically mounted flush with the heated surface. The diameter of the helically wound element coil is kept to a minimum, reducing the difference between the element and chamber temperature, thus ensuring long heater life. This feature enables the design and manufacture of responsive heating systems and significantly reduces the risk of overheating the element.

At 1150 C, power (watts) and current (amps) are 3.8% less (and resistance (ohms) is 3.8% more than the rated values.

In addition, Higher temperature ratings, up to 1700 C, are available with custom designs. This type heater is comprised of high quality molybdenum disilicide (MoSi2) heating elements.

Ceramic Fiber Module / Block:

Ceramic fiber Module / block adopts ceramic fiber blanket; Then it is folded and compressed to specified density. There are various anchor systems. The ceramic fiber blok is a new type of refractory furnace lining products aiming at simplifying and speeding up furnace construction and improving the integrity of furnace lining. This product has clean and white color as well as formal dimension, which can be directly fixed on the anchor nail on steel plate for shell of industrial furnace with excellent refractory and insulating effect. Thus, it has improved the refractory and insulating integrity of furnace and pushed forward the progress of furnace construction technology.

Ceramic fiber Module / block adopts ceramic fiber blanket; Then it is folded and compressed to specified density. There are various anchor systems. The ceramic fiber blok is a new type of refractory furnace lining products aiming at simplifying and speeding up furnace construction and improving the integrity of furnace lining. This product has clean and white color as well as formal dimension, which can be directly fixed on the anchor nail on steel plate for shell of industrial furnace with excellent refractory and insulating effect. Thus, it has improved the refractory and insulating integrity of furnace and pushed forward the progress of furnace construction technology.

Characteristic: | Application: |

Excellent chemical stability | furnace lining for furnace in petrochemical industry |

Excellent thermal stability | furnace lining for furnace in metallurgy industry |

Excellent tensility , after the construction of furnace lining is completed, the module is at the pre-compressed state; | Ceramic Industry: Tunnel and shuttle kilns for white ware, sanitary ware and brick firing Hoffman kilns |

Excellent thermal stability and thermal shock resistance | furnace lining for heat treatment furnace in heat treatment industry |

Excellent insulating performance and integrity of fiber furnace lining The installation of ceramic fiber blok is quick, and anchor parts are equipped on the cold surface of wall Lining. | Iron and steel Transfer ladle lids, soaking pit covers, reheating furnace, multi and single stack coil annealing furnace, continuous annealing and coating furnace, rotary hearth furnace, car bottom furnaces, roller furnaces, ductwork. |

The expansion of module make furnace lining be seamless and can make up the shrinkage of fiber furnace lining to improve heat insulation |

Physicochemical Index | ||||||||

Product | ||||||||

Saber blok | Uniblok | |||||||

1260 BLOK | 1400 BLOK | 1500 BLOK | 1600 BLOK | 1260 BLOK | 1400 BLOK | 1500 BLOK | 1600 BLOK | |

Classification temperature ( º C) | 1260 | 1425 | 1500 | 1600 | 1260 | 1425 | 1500 | 1600 |

Density(kg/m 3 ) | 160-190-220 | 160-190-220 | ||||||

Colour | White | white | Blue green | white | White | white | Blue green | white |

Linear Shrinkage ( C ×24h) | 1.3% 1100 C | 1.5% 1200 C | 1.1% 1300 C | 1.0% 1400 C | 1.3% 1100 C | 1.5% 1200 C | 1.2% 1300 C | 1.1% 1400 C |

Available size | 300(L)x300(H)x 150,200,250,300(T) | |||||||

.jpg)

.jpg)