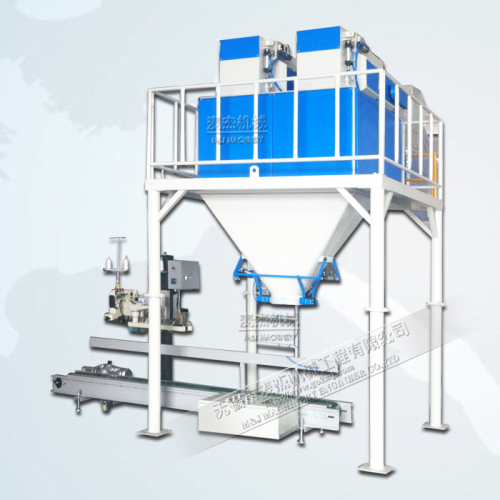

25kg starch flour valve filling machine valve bag packing machine for maize flour

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB,CFR,CIF,CIP,CPT,FCA,EXW |

| Payment Terms: | Paypal, L/C, D/P, D/A, T/T, WU, Money Gram |

| Supply Ability: | 50sets/month |

| Place of Origin: | Jiangsu |

Company Profile

| Location: | Wuxi, Jiangsu, China (Mainland) |

|---|---|

| Business Type: | Manufacturer |

Product Detail

| Means of Transport: | Ocean, Air, Land |

|---|---|

| Processing: | Packing Machine |

| Automatic Grade: | Semiautomatic |

| Type: | Special |

| Usage: | Outer |

| Packaging: | Others |

| Brand Name: | MJ |

| Application: | starch, corn flour, wheat flour,cocoa powder, cassava flour, maize flour |

| Automation: | semi automatic |

| Capacity: | 200-600bag/hour |

| Filling Accuracy: | 0.2% |

| Packaging Type: | 25kg bag, valve sack, paper bag, valve port bag |

| Manufacturer: | m&j machinery engineer |

| Operator: | 1-2 |

| Packaging Range: | 1kg, 5kg,25kg to 50kg, 5kg-50kg,10kg, 10-20kg,25 to 50 kilos, 25 kgs |

| Weighing system: | automatic display |

| Production Capacity: | 50sets/month |

| Packing: | plywood case |

| Delivery Date: | 20days |

Product Description

Applications

It is limestone powder packing machine, kraft paper bag filling machine, valve bagger, valve bag filling machine, valve sack filling machine that specially manufactured for materials quantitative automatically packaging into valve port bags by fixed weight such as 25kg, 30kg, 50kg. Suitable for cement, limestone powder, dry mortar, paint powder, silica powder, superfine powder, building powder, dry powder, talc filling into valve bags, etc.

Main Features

l Automatically measurement by computer, screw conveyer feeding-in or pneumatic feeding, continuously operation, accurate data;

l Using high-speed processing instruments and sampling frequency digital technology which can suit for different materials, easy to operate;

l Rational structure, small space, flexible installation and maintenance simple;

l Dynamic display, parameter storage, automatically saved data, balance pressure system, multi-function display and fault monitoring, automatic diagnostic techniques, multi-data communications interface, Standard communications interfaces, which used to print statements, easy-site management and centralized control of management;

l The main components are imported with high-grade.

Whatsapp me 0086-13914161862!(24-hour online)

Technical Parameters

Type: LCS-FK

Weighing Range: 1~5, 5~10, 10~25, 25~50 (KG), customized

Precision: ±0.2%FS

Power: 2 / 5.2 (KW)

Electrical Power: 380/220,50/60 (V/Hz)

Air Power: 0.4~0.6(Mpa)

Machine Video Link

To see more about our machine video

Youtube: M&J Machinery Engineer CO.,Ltd

Other Bagging Machines

About us

M&J Machinery Introduction and application

M&J Machinery Engineer Co., Ltd. is one of the leading packing solution suppliers in China and well-known in the packaging industries for its state-of-the-art packaging machines and its complete packaging lines for small- scale and large-scale production. Our product portfolio includes solutions such as bagging scales and feeders, bagging machines, valve bag fillers, jumbo bag filling machine, automatic packing palletizing plant, vacuum packaging equipment, robotic and conventional palletizers, stretch wrappers, conveyors, flow meters, etc. Moreover, M&J also offers bulk processing solutions as well as dry mortar plant and fish meal producing plant, including screening systems, batching system, mixing machine, dust collector, etc. M&J has authorized permit enterprise from the state and Jiangsu technical supervision department. And also the independent import/export license. M&J designs, produces and installs from single quantitative bagging machine to completed automatic bagging systems, and other large bagging projects. With our wide range of products and innovative solutions tailored to customers' specific needs, M&J is now an international leader in the field of industrial packaging equipment. In 2006, M&J obtained ISO9001-2008 certification. In the same year, it was awarded with the title of Quality Confirmed Firm.