River sand sea sand washing machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 150-200tph |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Rotary Lime Kiln China Professor, River Sand Sea Sand Washing Machine, Rock Crushers, ISO CE Jaw Crusher, 100tph Stone Crushing Line Machines |

Product Detail

| Model No.: | 2600 |

|---|---|

| Means of Transport: | Ocean, Air, Land |

| Application: | Others |

| Type: | Sand Washer |

| Brand Name: | Hongji |

| Name: | Sand washer, sand washing machine |

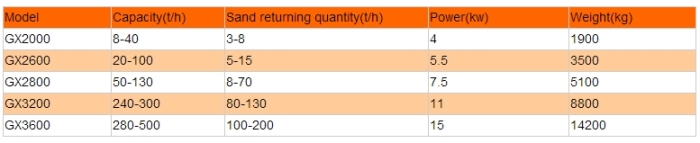

| Model: | GX3200 |

| Application: | building material, glass factory, concrete mixing plant, power plant, quarry plant, river & sea beach, valley |

| Capacity: | 160tph |

| Motor power: | 11kw |

| Weight: | 5600kg |

| Certificate: | ISO9001 , CE, IQNET,BV, SGS |

| Guarantee: | 12 month after instation |

| Service: | Engineer available oversea project |

| Spare parts: | Sieve SS304 supply all year long |

| Production Capacity: | 150-200tph |

| Packing: | Spare parts packing in wooden crate, main body nude packing load in container |

| Delivery Date: | Within 30 days after confirmed the order |

Product Description

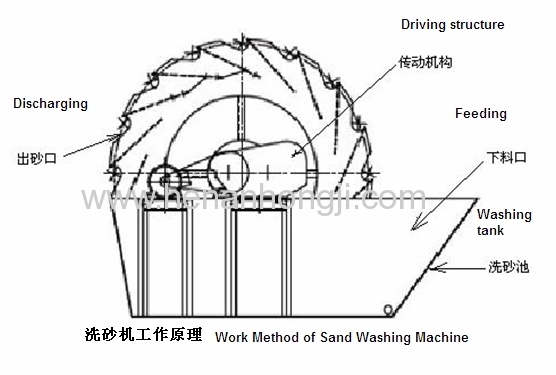

As China-based professional sand making and sand washing machine manufacturer, Henan Hongji Mine Machinery Co.,Ltd. adopt most advanced technology to produce our sand machines. The third generation sand maker with three types of crushing chamber, which contributes to high efficiency and low energy consumption. Sand washers can be divided into spiral sand washer and wheel sand washer, which can separate soil and foreign material from the sand effectively.

Sand washer is widely used for the washing of the material sand quarry, mining, building materials, transportation, chemical industry, water conservancy and hydropower, concrete mixing station, etc.

The raw material is transferred to jaw crusher for primary crushing by vibrating feeder, then the crushed material is transferred to sand-making machine through belt conveyor for secondary crushing. The materials crushed will be transferred to the vibrating screen. The material with suitable size will be transferred to sand washing machine, after being washed, then clean final products will be discharged. The other material with unsuitable size will be screened from vibrating screen, then will be transferred to the sand-making machine, this forms a closed and manifold cycles.this forms a closed and manifold cycles.

Q: Will the driving system broken easily as there are so many water and sand damaging it all the time?

A: We make separate part for driving system include gearbox, bearing, safe and closed working condition

Q: Need I buy many spare parts?

A: This machine wearing parts only the screening cloth

Q: What is the Screen cloth material? And how long can it work?

A: We use SS304, need change every 3-6 month

Q: Spare parts expensive?

A: Around $25-35/M2

Sand washing machine from Henan Hongji Mine Machinery Co.,Ltd.

Welcome your inquiry!

We will reply you within 12 hours.

.jpg)