Wood particles biomass three pass dryer machine

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 10 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Rotary Lime Kiln China Professor, River Sand Sea Sand Washing Machine, Rock Crushers, ISO CE Jaw Crusher, 100tph Stone Crushing Line Machines |

Product Detail

| Model No.: | 2612 |

|---|---|

| Application: | Others |

| Type: | Others |

| Brand Name: | Hongji |

| Machine name: | Triple drum rotary dryer |

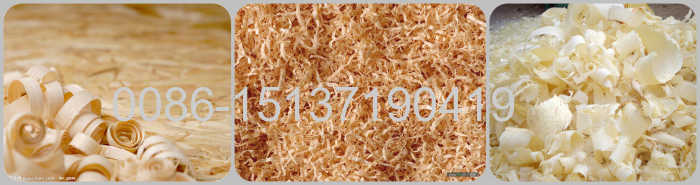

| Application: | Wood particles, biomass |

| Model: | 2600x12000m |

| Motor power: | 11kwx4 |

| Capacity: | 10tph |

| Moisture accept: | 35% |

| After drying moisture: | <5% |

| Fuel: | Oil, NG, Coal, Biomass etc. |

| Service: | Engineers available for oversea projects |

| Certificate: | CE ISO9001 |

| Production Capacity: | 10 sets per month |

| Packing: | Nude packing by container or bulk boat |

| Delivery Date: | 30 days after confimed the order |

Product Description

Machine introduction

Wood particles biomass Dryer also is named Wood Shavings Drying Machine. Wood Shavings Dryer is the key drying equipments for drying and dewarting wood shavings. It can dry the wood shavings from moisture 40-50% to moisture 8-15% which is suitable for storage, or according to the clients' requirements. The moisture inside the wood chips mainly are free water and biological water. Free water is easier to be dewatered, and biological water is difficult to be got rid of.

We Henan Hongji Company has been worked in the drying of wood chips, sawdust, wood shavings for more than 10 years. From then on, we have seen many different kinds of drying methods with varying degrees of success. Our past experience has proved that the most economic and efficient method for drying wood particle is to use of 3 pass rotary drum dryer.

Advantage

◆ Energy Saving: More economical to operate when fuel costs are taken into account.

◆ Big drying intensity. As wood shavings are high dispersion inside the flue gas, all superficial area of the wood chips (or wood shavings) are the effective drying area.

◆ Short Drying Time

◆ Compact Structure, Less occupied area, easy installation and maintenance.

◆ Large Capacity, High Heat Efficiency.

◆ Stable Quality Wood Shavings: Low breakage ratio, little smell of flue gas.

Feeding with 35% moisture wood particle

Drum Dryer body

Discharge after drying

Dry wood particle storage

Hongji three pass rotary drum dryer delivery

We Henan Hongji Mine Machinery Co., Ltd. is a professional mining machinery manufacture with ISO, CE Certificate, specialized in produce and develop various kinds mining machines for over 40 years, we are professional in:

- Stone crushing production line 5-500tph

- Sand making production line 50-200tph

- Ferro & Non ferro beneficiation process line (Au, Cu, Mo, Pb, Zn, Mn, Fe, Mn, etc)

- Industrial drying equipments (For sand, gypsum, filter cake, peat, biomass, clay, fertilizer, bentonite, Kaolin)

- Powder grinding equipments 80-200 mesh ( limestone, cement clinker etc)

- Cement/ Lime/ LECA production line with rotary kiln

Since 2008 the International Trade Department opened, we had export 44 countries and regions, rotary drying machines have been exported to Korea, Vietnam, Malaysia, Australia, Pakistan, Turkey, Spain, Azerbaijan, Russia, Kazakhstan, Uzbekistan, Bolivia, Panama, Argentina , Colombia and so on, with successful projects and excellent quality we have very good reputation from our clients.

Pre-sale:

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and choose best machine.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site.

4. Provide equipment list,design drawing, construction drawing, equipment install drawing.

During-sale:

1.Depend

on scene, draw design drawing , construction drawing, equipment install

drawing. 2.Manufacturing products strictly on contract while customer

constructing.

3.Testing ex-work, delivery, customer acceptance.

After-sale:

1.Provide engineer to wok site guiding install.

2.Test equipment after installation, training operators.

3.Visit work site regularly

Please do not hesitate to contact with us for more details!