Fly Ash Drying Machine 2015 New Arrival !

| Min. Order: | 1 Set/Sets |

|---|---|

| Trade Term: | FOB |

| Payment Terms: | L/C, D/P, D/A, T/T, WU |

| Supply Ability: | 10 sets per month |

| Place of Origin: | Henan |

Company Profile

| Location: | Zhengzhou, Henan, China (Mainland) |

|---|---|

| Business Type: | Manufacturer, Trading Company |

| Main Products: | Rotary Lime Kiln China Professor, River Sand Sea Sand Washing Machine, Rock Crushers, ISO CE Jaw Crusher, 100tph Stone Crushing Line Machines |

Product Detail

| Model No.: | 2560 |

|---|---|

| Application: | Others |

| Type: | Others |

| Brand Name: | Hongji |

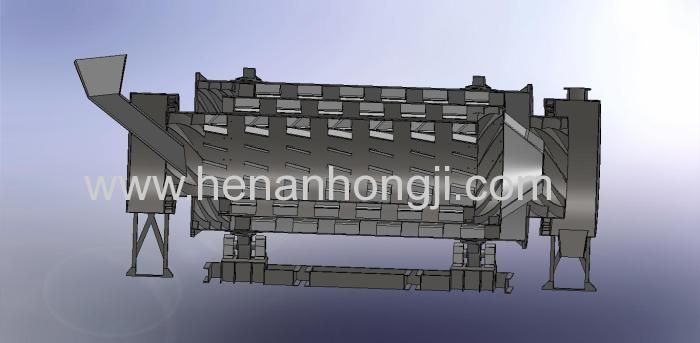

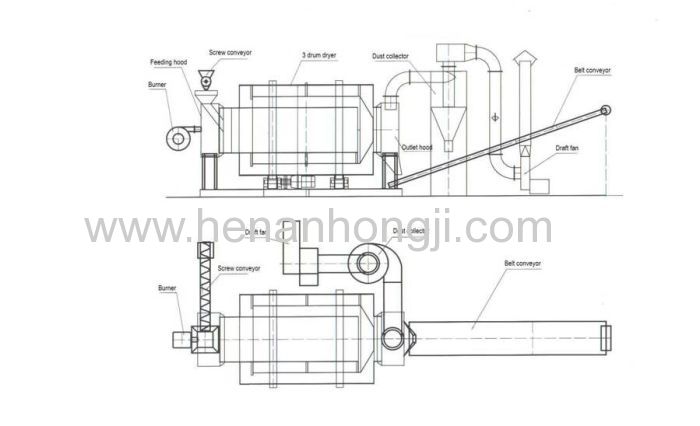

| Machine name: | Triple drum rotary dryer |

| Application: | Sand, fly ash, Clay etc |

| Model: | 3.0x6.5m |

| Motor power: | 11kwx4 |

| Capacity: | 35-45tph |

| Moisture accept: | 10-25% |

| After drying moisture: | <1% |

| Fuel: | Oil, NG, Coal, Biomass etc. |

| Service: | Engineers available for oversea projects |

| Certificate: | CE ISO9001 |

| Production Capacity: | 10 sets per month |

| Packing: | Nude packing by container or bulk boat |

| Delivery Date: | 30 days after confimed the order |

Product Description

In the coal fired power plant, the fly ash has two discharging style: one is dry discharging style, the other is wet discharging style.

In the rapidly developing cement industry, as the cement production mixing materials, the dry fly ash market is rather considerable. The physicochemical properties of wet fly ash are basicly same as the dry fly ash, but as there is big moisture content (maximum is amount to 45%), the wet fly ash can not meet the requirements of cement production. As a result, the wet fly ash can only be piled up as waste, and occupy many storage place, even pollutes the environment.

After years' research, Hongji Machinery developed one new type fly ash dryer. It has the advantages of low energy consumption, simple drying process, large drying capacity, etc. Fly ash dryer from Hongji Machinery can dry the wet fly ash from moisture content 45% to about 8% in large quantity directly.

◆ Low outlet temperature, long lifetime of dust cleaning system;

◆ Adopt new type lifting boards, and the output moisture content can be adjusted as customer's demand;

◆ High degree of automation, simple operation, stable working;

◆ Equipment investment needed is only 1/6 of the imported equipments. Low investment, creat profit quickly;

◆ Adopt gear transimission, small transimission power needed;

◆ Compared with single pass rotary drum dryer, it saves about 50% floor area, 60% electricity consumption;

◆ Broad fuel choice: coal, diesel, natural gas, waste wood, etc.

The drying process of 3 drum dryer is realized like this: material from the feeding end fed into the inner cylinder ,material into the inner tube through the spiral guide plate ,when tube rotating, the material continuously shifting and longitudinal movement by lifting plate, when the material reach the left of inner cylinder ,due to dead weight, fall into in middle cylinder, then through the guide plate, under the action of rotating cylinder body, material was pushed back in middle cylinder, the material right move under the action of lifting plate until the right end, the material into the outer cylinder under gravity . Raw material falls into outer tube by own gravity. Similarly, raw material turn back and towards the left by screw raising blades in outer outer, until to end of left side, and falls into cylinder of discharging end under the action of feed cone seal. Inside the 1, 2, 3 three concentric cylinders of Dryers subject, there are different numbers, different angles of spiral raising plates and each of ends of the cylinders with guide plates. Telescopic principals short cylinder drying machine through two geared motor 6, drive the driving wheel5 on opposite sides respectively, Make the belting leather 4 rotation around the center. Wet material need to dry through feeding device, feeding tube to feeding side of internal cylinder 3, the wet material quickly pushed into spiral raising board from spiral guide plate, along with the rotation of cylinder, screw lifting plate located within the four cylinder causes wet material constantly rolling, dispersed to end for vertical movement during lifting. At the same time, heat flow comes from stove successively enter into the inner barrel 3, middle barrel 2, external tube in 1 with material for heat exchange. Due to the metal plate is faster than drying materials in thermal conductivity, barrel of steel and feed plate heated first, and then pass heat to the material in the form of conduction and radiation, material heated, temperature will be up, when temperature rises to the water evaporation, water vapor from the separated material, along with the smoke through the filter into the atmosphere, thus achieve the goal of material drying.

We Henan Hongji Mine Machinery Co., Ltd. is a professional mining machinery manufacture with ISO, CE Certificate, specialized in produce and develop various kinds mining machines for over 40 years, we are professional in:

- Stone crushing production line 5-500tph

- Sand making production line 50-200tph

- Ferro & Non ferro beneficiation process line (Au, Cu, Mo, Pb, Zn, Mn, Fe, Mn, etc)

- Industrial drying equipments (For sand, gypsum, filter cake, peat, biomass, clay, fertilizer, bentonite, Kaolin)

- Powder grinding equipments 80-200 mesh ( limestone, cement clinker etc)

- Cement/ Lime/ LECA production line with rotary kiln

Since 2008 the International Trade Department opened, we had export 44 countries and regions, rotary drying machines have been exported to Korea, Vietnam, Malaysia, Australia, Pakistan, Turkey, Spain, Azerbaijan, Russia, Kazakhstan, Uzbekistan, Bolivia, Panama, Argentina , Colombia and so on, with successful projects and excellent quality we have very good reputation from our clients.

Pre-sale:

1. Depending on customer's requirement, we insist on "making profit at lowest investment" and choose best machine.

2. Design the most reasonable project and maximum customers' profit.

3.Provide engineers to scene to plan work site.

4. Provide equipment list,design drawing, construction drawing, equipment install drawing.

During-sale:

1.Depend on scene, draw design drawing , construction drawing, equipment install drawing. 2.Manufacturing products strictly on contract while customer constructing.

3.Testing ex-work, delivery, customer acceptance.

After-sale:

1.Provide engineer to wok site guiding install.

2.Test equipment after installation, training operators.

3.Visit work site regularly

Please do not hesitate to contact with us for more details about Fly Ash Drying Machine!